What You’re Missing in Your Symbia Gamma Camera QC

In this post, we’re going to be talking about something that you might not know about your Siemens Gamma Camera quality control.

We’re going to be talking about the very popular, widespread Siemens Symbia, and this post is going to cover every version of Symbia that’s out there, because for this purpose, the same issue is present.

What we’re going to be talking about is uniformity and how we evaluate the uniformity images on a Siemens Gamma Camera.

There’s one aspect of evaluating the uniformity images that a lot of technologists don’t really know. And unfortunately, the reason is because the essential information is buried in the quality control portion of the manual.

Watch the video above on our YouTube channel as Eric explains what you may be missing during your Siemens Symbia Gamma Camera quality control.

Deep inside the Quality Control portion of your Siemens Symbia gamma camera is a section on the criteria for evaluating the uniformity of images. Follow along as we show you where to find this important information.

Standard Uniformity Analysis

Often nuclear medicine technologists are taught to evaluate the quantitative part of the uniformity analysis by looking at the numbers and making sure that it’s less than 5%.

This is a general rule of thumb.

But for the Siemens system, there are actual values or limits that are associated with each of the four quantitative metrics that we get when completing daily quality control.

So, let’s dive into the quality control manual and show you what those metrics are and show you why it’s important. As a note, for this post, we are using the Operator’s Manual for the Siemens Symbia Intevo 16/6/2 and Intevo Excel Series.

Uniformity Values

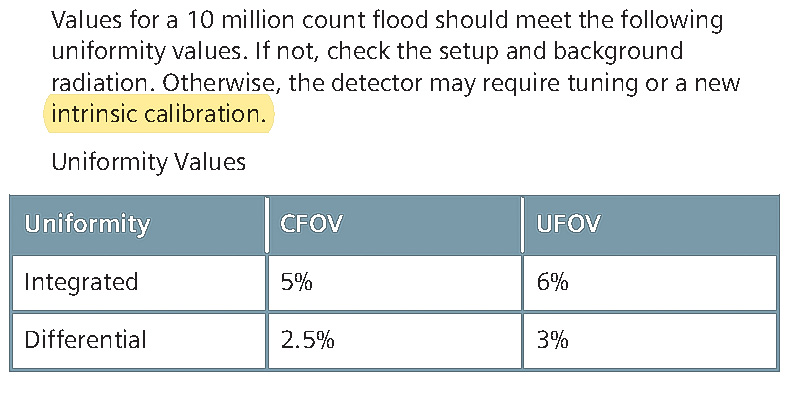

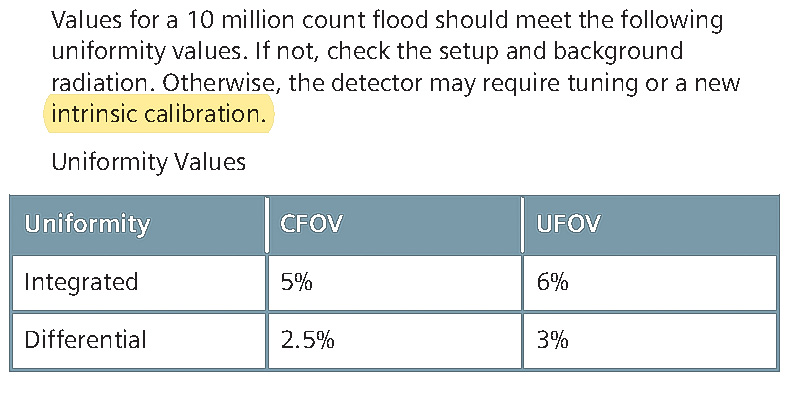

Within the Operator’s Manual, we can find the specific Uniformity Values by turning to the Quality Control and Assurance section.

For our example in this post, if you look on page 290, you can find a table with Uniformity Values. And while a general rule is to have values less than 5%, you can see from the table that each value is unique.

The table provides the values for Integrated CFOV, Integrated UFOV, Differential CFOV, and Differential UFOV.

Each of these values is different because each of measuring using unique criteria measuring a different physical aspect of the image. Note that these are all intrinsic values for 10 million counts.

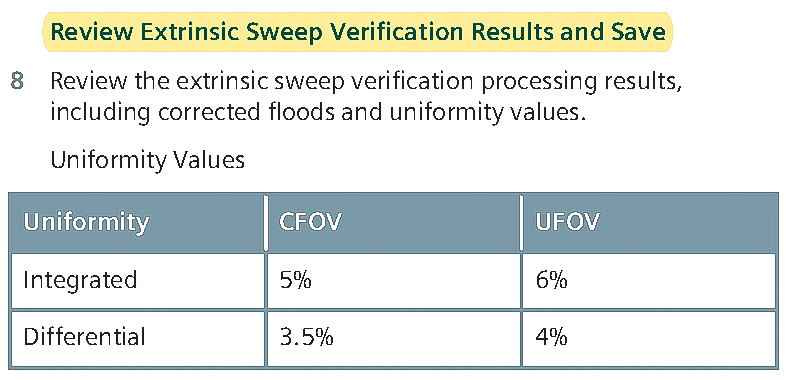

Now that we’ve found the intrinsic uniformity values, we can find the extrinsic values on page 301 of the Operator’s Manual in our example. We can see that this set of criteria are slightly different.

We still have 6% and 5% for the Integrated CFOV and UFOV. However, for the Differential, now we’re at 3.5% for CFOV and 4% for UFOV.

Whenever we’re doing our flood images, we need to make sure that we’re looking at the intrinsic criteria for any intrinsic floods that we’re doing, and we’re should be looking at the extrinsic criteria for any extrinsic floods that we’re doing. Again, these are for 10 million count floods and this is for the intrinsic verification or the extrinsic verification.

Example of a Uniformity Value Comparison

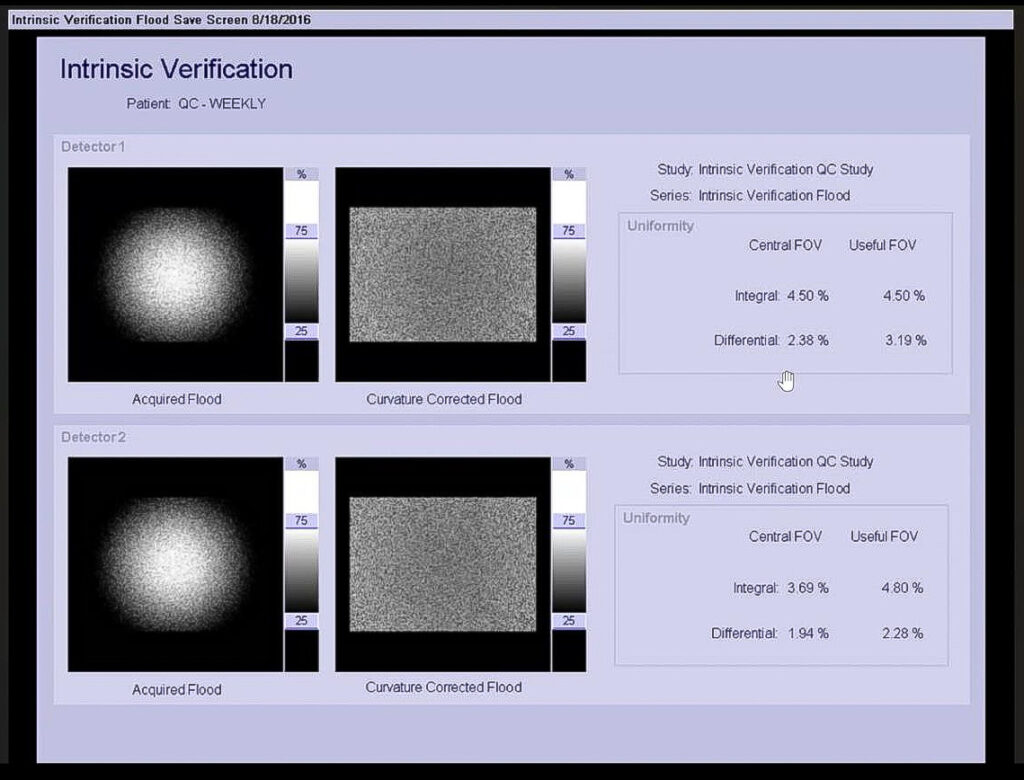

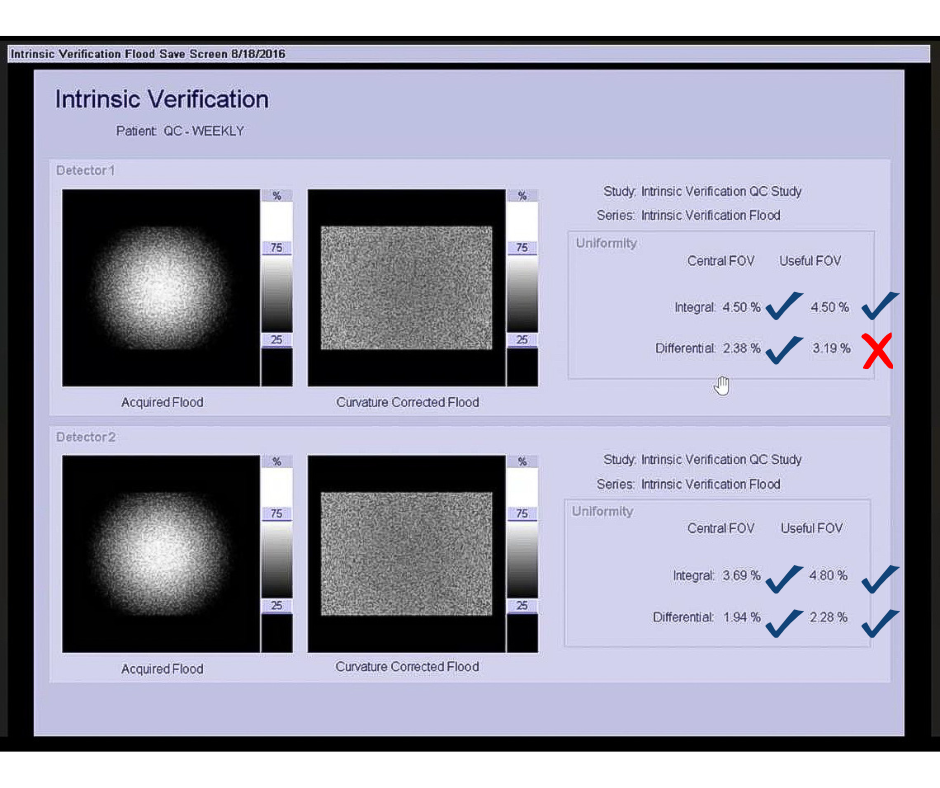

In this example, we will use an intrinsic verification from a Siemens MBA. When we look at each of the numbers. The reason we use this specific example is because there is no indication on the screen image that this flood actually didn’t pass.

So which criteria did not pass?

Side-By-Side Analysis

Let’s just do a side by side against what the intrinsic values are versus what we actually calculated or measured.

When reviewing the image results with the actual values in the Operator’s Manual Quality Control section, we can see that we’re fine with everything here except for Detector 1, Integrated UFOV. This value shows 3.19%, yet the criteria is only 3%.

There is no indication on the screen that one of the values hasn’t passed the QC standard. This is somewhat problematic with the Siemens systems because you don’t actually know whether you pass or fail the criteria automatically. You have to apply the criteria from the manual to determine whether or not you pass or fail the the test.

What Do You Do If a Value Fails?

So if you have a value that fails like this 3.19%, when the criteria is 3%, what do you do?

The first thing we recommend to people to do is to go through a tuning and peeking exercise on the equipment. Go through the tuning and peaking exercise, do all of the things that you can run before you get to the uniformity test and then rerun the flood.

Oftentimes that will correct the issue. If that doesn’t correct the issue, you can go back in and rerun and an intrinsic calibration. When you run an intrinsic calibration, we sometimes call that a high count flood. With the Siemens systems, you need to do at least 120 million counts.

Oftentimes they’re set to 200 million counts, and this can be quite timely. But when you’re redoing that intrinsic calibration you’re going to smooth out any non uniformity that you see in the intrinsic verification. When you do the intrinsic calibration, there is a specific criteria associated with it that you can find in the manual.

For intrinsic calibrations, we say that they can compensate for values up to about 10%. If you exceed 7% for the calibration, then you need to contact service. If your intrinsic calibration passes and you don’t see any issues, you’re below the 7% on the intrinsic calibration.

Now you can rerun your intrinsic verification or daily flood and see if you you pass those values. If you are still not passing those values, that’s the point that you should probably contact either service or contact your physicist to try to get some direction on what it is that you need to do in order to get your camera to pass the manufacturer stated specifications.

A Common Misconception

There’s a common misconception that the screen will turn red if a Verification Flood value fails. As long as it doesn’t turn red, you’re going to be fine.

That’s actually not true with the Siemens systems. You have to pay attention to what the values are and evaluate against what’s in the manual to determine whether or not your uniformity images are actually passing the manufacturer’s specifications.

We hope that this article and video has provided you with awareness of things to consider when testing your Symbia Gamma Camera to ensure it pass the manufacturer’s standards. If you have questions or comments, please reach out to us at [email protected] and we’d be happy to assist you.

Your medical physicist is a great resource for you when designing your Quality Control Program, nuclear medicine testing, and ACR accreditation. You can also always reach out to us if you have questions or want more information on why you should partner with us.